Fabric 101- All you need to know

- NANCY NGUYEN

- Feb 1, 2019

- 3 min read

The textile industry is extremely diverse producing a wide range of fabric within the area of woven fabrics alone. Industrial, domestic and high fashion fabrics for apparel are woven using one or combinations of the many different weaves available , these combines with the range of colours and the many finishes that can be applied results in an amazing range and variety.

The definition of a woven fabric is one that has a warp (length) and weft (width), and therefore a grain or direction.

The type of weave gives character to the fabric whether it be a simple plain weave of something more complicated. Weaving sometimes involves intricate patterns, but all weaves fall into two main categories: simple construction and compound construction.

1. SIMPLE WEAVE CONSTRUCTION - PLAIN WEAVE

There are three categories of plain weave. The first category is itself divided into basket and repp. The second category comes in twill and herringbone types, while the third category is satin and sateen weaves.

1.1 Plain weave

The structure of repp weave (or rep weave) is: one over and one under (as for plain), but with warp of weft heavier than the other, thereby forming a rib which makes the fabric stronger. Repp weave forms a popular furnishing fabric.

Plain Weave Textile

1.2 Twill weave

The structure of Twill weave (or rep weave) is: one under and two over which moves along one space to create a diagonal line. Herringbone weave is a twill weave with a definite number of steps to the right and the same number to the left.

Twill Weave (left) and Herringbone Weave (right)

1.3 Satin and Sateen

The unique weaving pattern shared by both fabrics is four threads over and one thread under. This maximizes the visible threads on the top side of the fabric, giving it that trademark luxurious and elegant softness and shine. Likewise, the other side of the fabric has a dull appearance, establishing a decided “right side.”

Though the weave is very similar, as is the appearance and texture, however, satin and sateen are made from different fibers. Originally, satin was made from 100% silk thread. Indeed, the higher quality satin still is. For durability, maximum shine, and cost effectiveness, satin is now made from nylon or polyester – frequently a blend of all three. While satin made from synthetic fibers tends not to breathe so easily as natural silk, the effect of the fabric is very much the same.

Sateen, on the other hand, is made entirely from cotton (sometimes rayon). Typically, the cotton used is carded, combed, or mercerized to assist with the characteristic “silkiness.”

2. COMPOUND WEAVE CONSTRUCTION

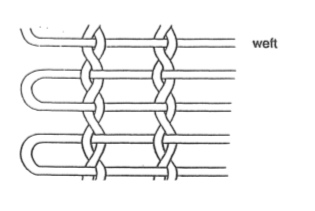

2.1 Leno (Gauze) Weaves

In this compound weave, two warp threads are twisted around one weft thread to form a knot. Scrims are woven this way.

Fabrics made by Leno weave include marquisette (It is a sheer, light weight, leno weave fabric, usually made of filament yarns), mosquito netting, agritextiles to shade delicate plants, and some bags for laundry, fruit and vegetables. Polyester marquisettes are widely used for sheer curtains.

Leno Weave structure

For more photos about marquisette fabric please visit: https://www.designersguild.com/uk/fabric/designers-guild/marquisette-fabrics/c586

2.2 Double Cloth and Double Faced Fabric

Double-cloth fabrics are made of two fabrics threaded or fused together to form a thicker and more substantial fabric. You can actually take the fabric edge and peel apart the two fabrics. This allows you to create beautiful garments that are completely reversible, with no lining necessary.

Double-faced fabrics are also fabrics where either side can be used, but unlike double cloth, these fabrics have only one layer of fabric and cannot be separated. At Mood we love an attractive double-faced fabric, because it offers our customers so many design options when they have two sides of fabric to work from: Satin or matte side? Print or solid side? Jacquard or reverse jacquard?

Double-cloth (left) and Double-faced (right) fabric

2.3 Pile Weave

Pile weave are made with upstanding ends, like fur. One set of warps is joined with the weft to form a smooth, solid back. Chenille, velvet and moquette are pile weaves

Pile weave weaving technique

Chenille, Velvet and Moquette

3. NON WOVEN FABRIC

3.1 Net and Laces

Nets and laces are knitted, not woven on a loon, and hence does not have a warp and weft grain. They are either made by hand or in a machine.

Net and Lace Fabric

3.2 Felt

Felt is produced from wool fibres. The fibres are matted together under moisture into a wad and then fabric is form using steam and pressure. Felt is strong and resilient but non- elastic and stiff, well insulating properties but poor drapability. Medium-weight wool felt is used for furnishings and mats when heavy-weight wool felt is used many for floor coverings.

Felt Fabric

3.3 Bonded Fabric

These are made similarly to felt but are of other fibres than wool. They are formed into a mat or wad and then converted into fabric by chemical and mechanical bonding. The four types are wet-bonded, needled, melded and spun-bonded.

Bonded Fabric

Reference:

All credit belongs to @RMITUniversity

2.1 https://textileapex.blogspot.com/2015/03/characteristics-end-usages-of-gauze-fabric.html

img http://www.itextiles.com/v30/itext/thumbnails/term_3_191.htm

2.2 https://www.moodfabrics.com/blog/fabric-101-double-cloth-and-double-face-fabrics/

2.3 https://www.theweavingloom.com/weaving-techniques-the-pile-weave-loop-weave/

https://www.wisegeek.com/what-is-chenille.htm#pink-chenille

Comments